White_Wolf

Master at Arms

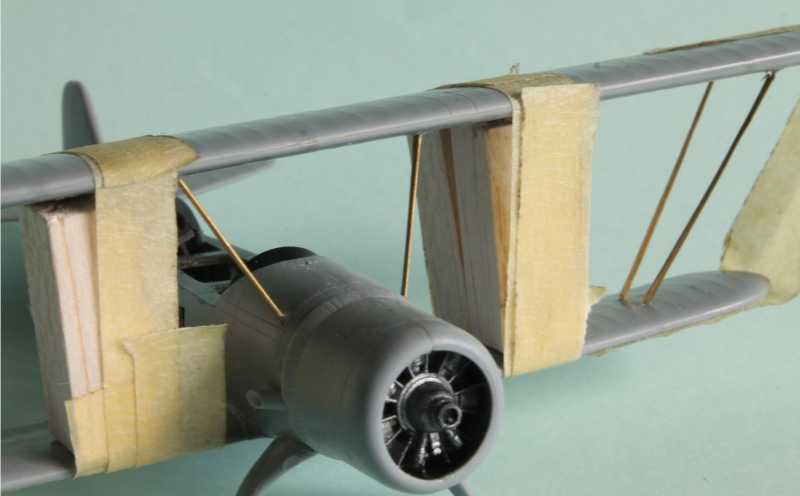

I'm interested in how you handle those flarings around the turnbuckles attached to the bottom of the top wing. My perpetually stalled P6 Hawk has those, they are there to cover the turnbuckles and aid in aerodynamics.

I am handling them very well at the moment ...not thinking about them

I'll have to think of something soon though, keep you upted, I think I'm going to try a couple of things ...

Laurence

... Following with full attention

... Following with full attention  I should think your brass struts would have quite a lot more strength than the plastic strut replacement stock does. Have you considered bitty pieces of tamiya tape for the turnbuckle gloves?

I should think your brass struts would have quite a lot more strength than the plastic strut replacement stock does. Have you considered bitty pieces of tamiya tape for the turnbuckle gloves?