Little update. I remade the top to the center console to more closely match the reference. I used 3 layers of .03" styrene. The top layer got circle punched. The drink holder circles should be 6mm but the biggest I have is 5mm so it will have to do. The middle layer had a cutout where the drink holders are to make them a little deeper and the layer forms the bottom of the change troughs. The 3rd layer forms the bottom of the drink holders.

The top was framed with 2mm quarter round styrene cut at 45° angles. The hinge is made of 1/25 scale heater hose to provide friction so the lid will stay open.

The brass rod is glued to the underside of the lid, then encased in thin styrene.

The seat backs have the pivot arm attached. I used .02 styrene trying to keep it in scale. It is glued with Tamiya X thin.

I set the seat back in place and drilled a hole for the .062 brass tube. I have little metal rivets coming to put through the hole to hold the seat back in place. It folds down easily

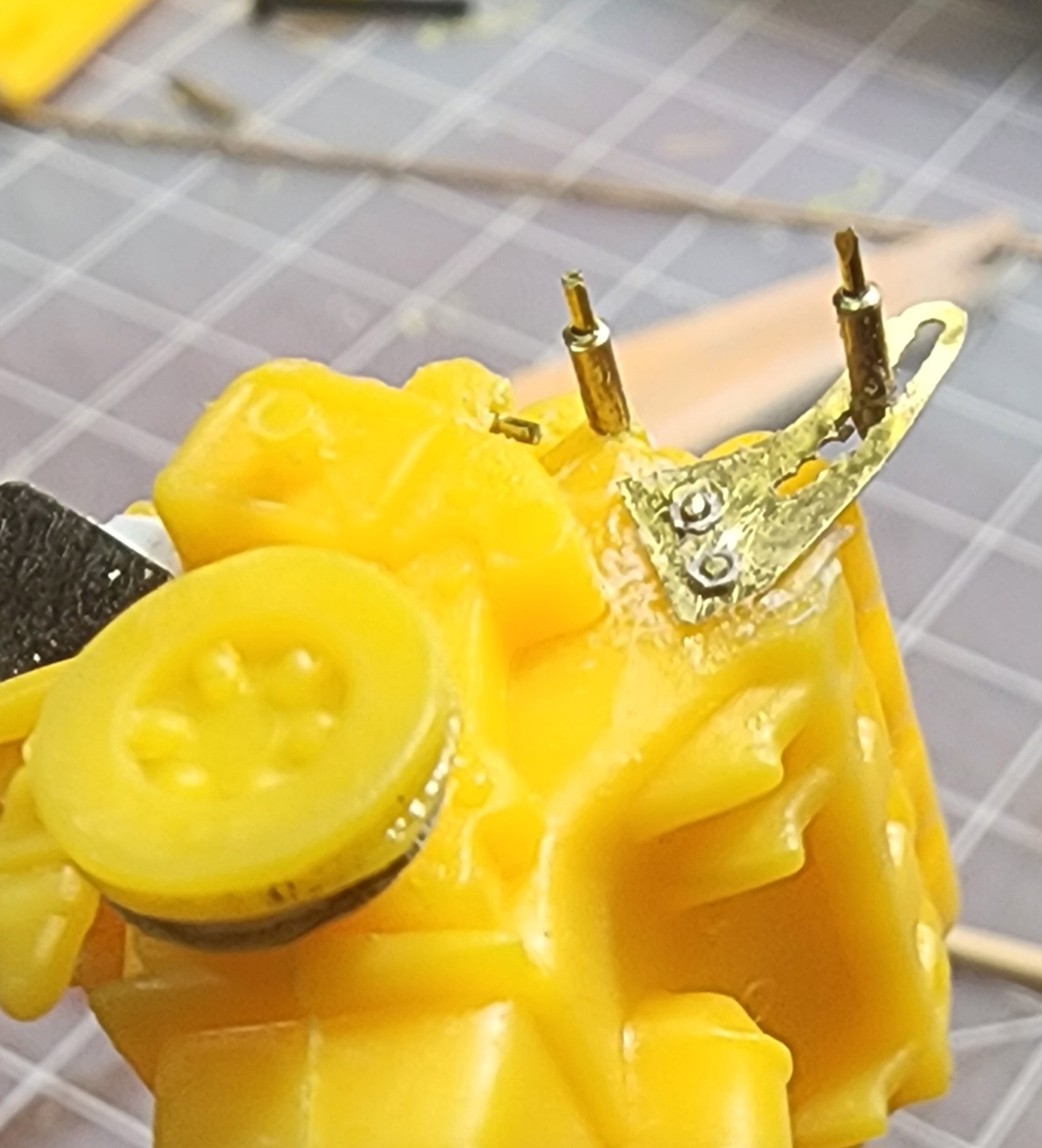

On the passenger side, which folds forward to allow back seat access, is hinged with brass rod and tube

The 2 tubes at each end are CA'd in place on the rod, and the center tube will be epoxied or CA'd to the interior base.

Speaking of hinges, I finally figured out how to hinge the rear window using a similar hinge I used on the seat. I used .04" tube, the smallest I have, and matching .02 rod to make a 3 part tube and rod hinge. I crimped the ends of the rod to keep the tubes from sliding off.

The hinge is inset into the window edge. I should have inset into the body frame, but I misread the photo. It works though.

The tailgate is held closed with 2 tiny earth magnets. It stayed closed before, but now it has a very satisfying click when it closes.

The doors are hinged and work well.

The next step for the doors is to create spacers to add the proper thickness between the skin and inner door surface.

That's about it. Thanjs for looking!